|

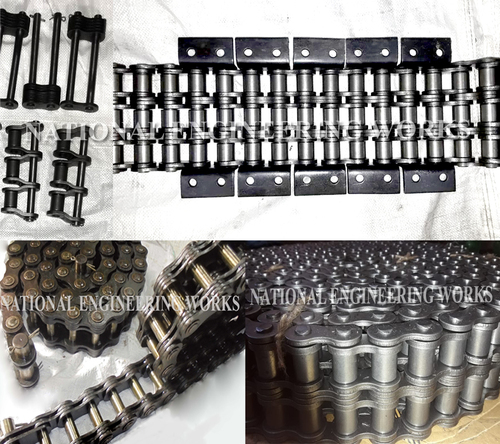

Wet Scraper Chain Link

Wet Scraper Chain Link Specification

- Usage & Applications

- Wet Scraper Conveyor Systems, Industrial Material Handling

- Bore Size

- As per requirement

- Product Type

- Wet Scraper Chain Link

- Material

- Alloy Steel

- Surface Treatment

- Polished

- Teeth Number

- 16

- Size

- Standard/Customizable

- Strength

- High Tensile

- Packaging Type

- Wooden Box/Carton

- Pin Diameter

- 8 mm

- Hardness

- 55-60 HRC

- Operating Temperature

- -20C to 250C

- Manufacturing Process

- Precision Casting

- Corrosion Resistance

- Yes

- Color

- Metallic Grey

- Chain Link Thickness

- 12 mm

About Wet Scraper Chain Link

We manufacture a wide assortment of Drop Forged Forked Chain Links (76 216 mm pitch) for transportation of abrasive material in hot working condition. Mostly incorporated in application like Heavy-Duty Drag Chain Conveyors, Wet Scrapers, Boiler Feeders & Mill Hoppers, Ash Handling Conveyors, ESP Dust Conveyors, En-Masse Conveyors, Reclaimer & Intermediate Carriers etc, the chain links are manufactured from age resistant fine grained heat treatable alloy steel and stainless steel, heat treated to surface hardness more than 550 HV having breaking strength up to 600 N/ SQ mm. Salient note-worthy features of our Chain Links are :

- Closed die drop forged to attain compact grain construction

- Inner portion of Fork precisely machined ensuring minimized friction and wear

- Inside load bearing pivots inductively hardened

- Case hardened up to RC 55, case depth from 0.7 mm to 1.0 mm for abrasive application

- Through hardened for higher U.T.S during high tensile application to bear impact load

- Duly normalized and stress relieved to preserve grain structure to impart optimum breaking strength

Within a complete linear arrangement or loop, flights and scraper blades are usually incorporated at every single or predetermined pitch. These chains can be supplied preassembled with case hardened joint pins and can be smeared with protective coating. Forged Block type Chain Links can also be developed to meet customers specification and requirements.

Unmatched Corrosion Resistance

Thanks to its specialized alloy steel composition and polished surface treatment, the Wet Scraper Chain Link delivers outstanding resistance against corrosion. This durability ensures reliable operation even in harsh industrial environments, minimizing maintenance needs and contributing to longer service life.

Customizable for Your System

Whether you need a standard or a uniquely tailored chain link, this product offers flexibility in size and bore specifications. Adapt the component precisely to your conveyor systems requirements, supporting efficient material movement within diverse industrial sectors.

FAQs of Wet Scraper Chain Link:

Q: How is the Wet Scraper Chain Link manufactured and what ensures its durability?

A: The chain link is produced using a precision casting process from high-tensile alloy steel. Its durability is further enhanced by a polished finish and a surface hardness of 55-60 HRC, making it particularly suited for heavy-duty industrial applications.Q: What applications are most suitable for this Wet Scraper Chain Link?

A: This chain link is primarily designed for wet scraper conveyor systems used in industrial material handling. Its strength, corrosion resistance, and adaptability make it ideal for rigorous environments demanding reliable movement of materials.Q: When should I consider customizing the size or bore of the chain link?

A: Customization is recommended when your conveyor system requires non-standard dimensions to ensure optimal fit and function. Tailoring the bore size as per your application guarantees smoother and more secure integration in your operations.Q: Where can this chain link operate effectively in terms of temperature range?

A: The product is engineered to function reliably in environments with temperatures spanning from -20C to 250C, making it suitable for both cold storage facilities and high-temperature industrial processes.Q: What are the benefits of the chain links corrosion resistance and polished finish?

A: Corrosion resistance ensures the chain link will withstand moisture and chemicals, reducing the frequency of replacements. The polished finish aids in minimizing material build-up and wear, contributing to its longevity and maintaining system efficiency.Q: How is the product delivered and packaged to ensure safety during transit?

A: Each unit is securely packed in either a wooden box or a carton, providing robust protection against damage during transport for distributors, manufacturers, suppliers, and traders across India.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Scraper Chain Category

Scraper Reclaimer Chain

Price 15000 INR / Meter

Minimum Order Quantity : 100 Meters

Teeth Number : Custom as per design requirement

Front Gear : Compatible with standard sprockets

Product Type : Other, Scraper Reclaimer Chain

Usage & Applications : Bulk Material Handling, Cement Plants, Mining Industries

Scraper Chain for Stacker And Reclaimer

Price 10000.00 INR / Meter

Minimum Order Quantity : 100 Mtr

Teeth Number : As per design/specification or customer requirements

Front Gear : Compatible with OEM equipment; dimensions as per requirement

Product Type : Other, Scraper Chain for Stacker and Reclaimer

Usage & Applications : Material handling, stacking and reclaiming equipment in mining, cement, power, steel and port industries

Forged Forked Drag Chain Link & Sprocket Wheel

Minimum Order Quantity : 100 Pieces

Teeth Number : Varies by application

Front Gear : Forged Front Gear

Product Type : Other, Forged Forked Drag Chain Link & Sprocket Wheel

Usage & Applications : Industrial machinery conveyor systems

|

NATIONAL ENGINEERING WORKS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry