Most Popular Products

|

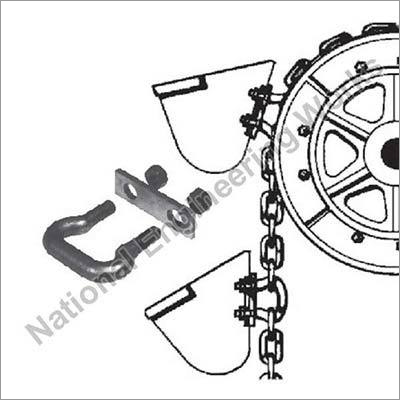

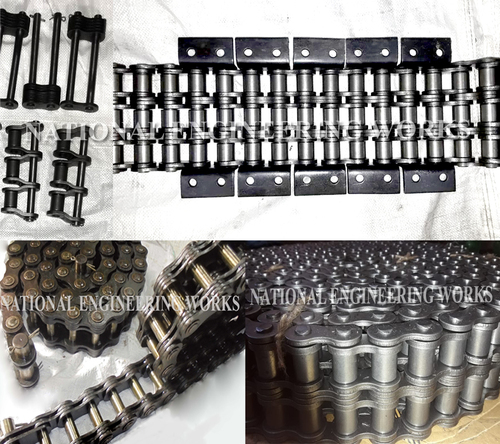

Heavy Duty Bushed Elevator Chains

Price 100 INR/ Meter

MOQ : 100 Meters

Heavy Duty Bushed Elevator Chains Specification

- Bore Size

- Customizable as per requirement

- Usage & Applications

- Elevator Conveyors, Handling Bulk Materials, Cement Plants, Mining, Fertilizer Plants, Grain Processing

- Product Type

- Heavy Duty Bushed Elevator Chain

- Material

- Alloy Steel / Carbon Steel

- Surface Treatment

- Heat Treated & Zinc Plated

- Teeth Number

- Customizable as per elevator design

- Front Gear

- Available upon request

- Rear Gear

- Available upon request

- Size

- Standard and Custom Sizes

- Working Life

- Extended life for heavy-duty applications

- Maintenance

- Low maintenance design

- Breaking Load

- Up to 90,000 kgf

- Pitch

- 4" to 8" (102 mm to 203 mm)

- Corrosion Resistance

- High due to surface treatment

- Packaging

- Wooden Box / Custom Packaging

- Roller Diameter

- 50 mm to 150 mm

- Lubrication

- Pre-lubricated for optimal performance

- Chain Type

- Straight & Offset Side Bar

- Quality Standards

- Manufactured as per IS & DIN standards

- Pin Diameter

- 19 mm to 36 mm

- Temperature Range

- -10°C to +250°C

Heavy Duty Bushed Elevator Chains Trade Information

- Minimum Order Quantity

- 100 Meters

- Payment Terms

- Cash in Advance (CID), Cash Advance (CA)

- Supply Ability

- 100 Meters Per Month

- Delivery Time

- 90 Days

- Packaging Details

- Bushed construction: A bushing is placed between the pin and the inner link, reducing the direct contact and friction that would otherwise cause wear. High strength and durability: Engineered from materials like carbon or alloy steel, with hardened pins and bushings, these chains offer high fatigue strength and shock-loading capabilities. Wear and elongation resistance: The bushed design minimizes wear, which prolongs the chain's life and makes it more resistant to elongation from continuous use. Designed for heavy loads: They are built to withstand continuous dynamic loads, making them ideal for applications like bucket elevators and material handling systems. Corrosion resistance: Often made with corrosion-resistant materials or finishes, making them suitable for harsh industrial environments. Versatility: Available with various welded or integral attachments to suit different conveying applications.

- Main Export Market(s)

- Asia

- Main Domestic Market

- All India

- Certifications

- Bushed construction: A bushing is placed between the pin and the inner link, reducing the direct contact and friction that would otherwise cause wear. High strength and durability: Engineered from materials like carbon or alloy steel, with hardened pins and bushings, these chains offer high fatigue strength and shock-loading capabilities. Wear and elongation resistance: The bushed design minimizes wear, which prolongs the chain's life and makes it more resistant to elongation from continuous use. Designed for heavy loads: They are built to withstand continuous dynamic loads, making them ideal for applications like bucket elevators and material handling systems. Corrosion resistance: Often made with corrosion-resistant materials or finishes, making them suitable for harsh industrial environments. Versatility: Available with various welded or integral attachments to suit different conveying applications.

About Heavy Duty Bushed Elevator Chains

Heavy-duty bushed elevator chains areindustrial chains designed for high-load and harsh-condition applications, such as bucket elevators and conveyors. Their robust design features a precision-engineered "bushed" construction where a bushing protects the pin from wear, minimizing friction and increasing durability. This construction provides superior strength and wear resistance, extends service life, and allows them to handle continuous heavy loads and shock loading effectively.

Key features and benefits

- Bushed construction:A bushing is placed between the pin and the inner link, reducing the direct contact and friction that would otherwise cause wear.

- High strength and durability:Engineered from materials like carbon or alloy steel, with hardened pins and bushings, these chains offer high fatigue strength and shock-loading capabilities.

- Wear and elongation resistance:The bushed design minimizes wear, which prolongs the chains life and makes it more resistant to elongation from continuous use.

- Designed for heavy loads:They are built to withstand continuous dynamic loads, making them ideal for applications like bucket elevators and material handling systems.

- Corrosion resistance:Often made with corrosion-resistant materials or finishes, making them suitable for harsh industrial environments.

- Versatility:Available with various welded or integral attachments to suit different conveying applications.

Common applications

- Bucket elevators in industries like grain handling, food processing, and mining.

- Conveyor systems for heavy-duty material handling.

- Other industrial applications requiring high strength and reliability under continuous stress.

Engineered for Demanding Applications

Our heavy-duty bushed elevator chains are designed for abrasive and heavy-load environments like mining, cement, fertilizer, and bulk grain handling. With robust construction and superior surface treatments, these chains deliver sustained performance and extended operational life, even when exposed to challenging temperatures and continuous operation. Every component is manufactured to meet strict IS and DIN standards, ensuring consistent reliability and safety in critical material handling systems.

Custom Solutions and Superior Quality

Choose between standard or fully customized elevator chains tailored to your applications pitch, bore size, and gear requirements. Manufactured using premium alloy or carbon steel, each chain undergoes precise heat treatment and advanced zinc plating for uncompromising durability and corrosion resistance. Our distribution across India ensures timely delivery, while custom packaging options further support safe international transport and installation.

FAQs of Heavy Duty Bushed Elevator Chains:

Q: How do Heavy Duty Bushed Elevator Chains ensure long working life in harsh environments?

A: These chains are constructed from high-quality alloy or carbon steel and receive specialized heat treatment and zinc plating, providing superior strength and high corrosion resistance. Pre-lubrication, robust design, and adherence to IS & DIN standards all contribute to extended working life and reduced maintenance needs in abrasive or corrosive settings.Q: What types of industrial applications are best suited for these elevator chains?

A: Heavy Duty Bushed Elevator Chains excel in bulk material handling, particularly within cement plants, mining operations, fertilizer processing, and grain handling facilities. Their reliability and robust build make them ideal for elevator conveyors encountering high loads and continuous usage.Q: When should I consider customizing the pitch, gear, or bore of the chain?

A: Customization is recommended when your equipment calls for specific dimensions or compatibility, such as unique pitch lengths, non-standard bore sizes, or matching front or rear gear configurations. Customizing ensures seamless integration, optimal performance, and longevity for your bulk handling system.Q: Where are these elevator chains manufactured and distributed?

A: Our elevator chains are manufactured and supplied across India, following strict IS & DIN standards. As a distributor, manufacturer, supplier, and trader, we offer reliable availability and support for both national and international clients.Q: What is the process for ordering customized elevator chains?

A: First, share your applications specifications, such as pitch, bore size, teeth number, and gear requirements. Our technical team will design and manufacture the chains to your exact needs, ensuring compatibility and optimal performance. Chains are carefully packaged in wooden or custom boxes for secure delivery.Q: How does the low-maintenance design benefit operators and plant managers?

A: The low-maintenance design, combined with pre-lubrication and corrosion-resistant surface treatments, significantly reduces routine servicing. This leads to shorter downtime, lower maintenance costs, and improved operational efficiency in high-demand applications.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Bucket Elevator Chain Category

Bucket Elevator Link Chain ends

Minimum Order Quantity : 10 Pieces

Material : Stainless Steel

Warranty : 1 Year

|

NATIONAL ENGINEERING WORKS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry