Most Popular Products

|

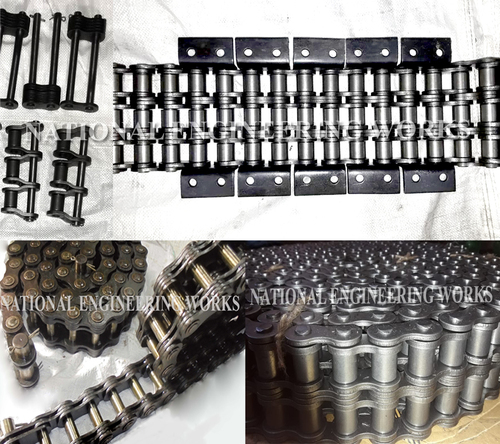

Inverted Tooth Conveyor Chains

Price 10000 INR/ Piece

MOQ : 100 Meters

Inverted Tooth Conveyor Chains Specification

- Bore Size

- Customizable

- Usage & Applications

- Conveyor systems, Industrial material handling

- Product Type

- Inverted Tooth Conveyor Chain

- Material

- Alloy Steel

- Surface Treatment

- Heat Treated for Durability

- Teeth Number

- Varies as per chain specification

- Front Gear

- Available as per design

- Rear Gear

- Available as per design

- Size

- Custom sizes available

- Pitch

- Standard and customized available

- Maintenance

- Low maintenance, long service life

- Lubrication

- Oil or grease as required

- Assembly Type

- Riveted and cottered options

- Chain Width

- Up to 60 mm or as per requirement

- Operating Temperature Range

- -20°C to +120°C

- Roller Type

- Integrated or optional

- Delivery Condition

- Ready for installation

- Breaking Load

- High tensile strength

- Corrosion Resistance

- Enhanced with specific surface treatments

- Tensile Strength

- Up to 50 kN

Inverted Tooth Conveyor Chains Trade Information

- Minimum Order Quantity

- 100 Meters

- Payment Terms

- Cash in Advance (CID)

- Supply Ability

- 100 Meters Per Month

- Delivery Time

- 90 Days

- Main Domestic Market

- All India

About Inverted Tooth Conveyor Chains

Inverted Tooth Conveyor ChainsFlat top bearing surface of the Inverted Tooth Conveyor Chain guarantees stability of the products being conveyed. All Link, Link and Spacer and Extended Pitch arrangements can be offered for IS machine conveyors or cross conveyors along with corresponding Gear .

Robust Build and Superior Performance

Our Inverted Tooth Conveyor Chains are constructed using high-grade alloy steel and benefit from advanced heat treatment processes. This provides outstanding tensile strength and ensures the chains perform reliably even under the most challenging conditions, making them suitable for a wide range of demanding industrial applications.

Customization to Fit Your Needs

Whether you require a standard or fully customized solution, these chains can be tailored in terms of pitch, width, teeth number, and bore size. Surface treatments enhance corrosion resistance while roller types and assembly options offer additional flexibility for diverse operational requirements.

Effortless Installation and Maintenance

Designed for convenience, each chain is delivered in a ready-to-install condition. Optional lubrication methods, low maintenance requirements, and integrated rollers contribute to a prolonged service life, reducing operational downtime and increasing efficiency for conveyor systems and material handling operations.

FAQs of Inverted Tooth Conveyor Chains:

Q: How are inverted tooth conveyor chains installed and maintained?

A: These chains are supplied ready for installation, making setup straightforward. Depending on your application, they come with either riveted or cottered assembly types. Maintenance is minimal, usually involving periodic lubrication with oil or grease to ensure smooth operation and longevity.Q: What customization options are available for these conveyor chains?

A: You can customize several features including pitch, chain width (up to 60 mm or as needed), teeth number, bore size, and roller type (integrated or optional). Specialized surface treatments for enhanced corrosion resistance and a choice of front or rear gears are also available to best match your application.Q: Where can these conveyor chains be effectively used?

A: Inverted tooth conveyor chains are ideal for industrial material handling systems and conveyor applications across multiple sectors. Their robust design makes them a preferred choice for environments where high tensile strength, low maintenance, and reliable performance are crucial.Q: What is the typical operating temperature range for these chains?

A: These chains perform efficiently in a temperature range from -20C to +120C, making them suitable for a broad spectrum of industrial environments, from cold storage facilities to high-temperature processing plants.Q: How is durability ensured in the construction of these chains?

A: Manufactured from high-quality alloy steel and subjected to heat treatment, these chains exhibit superior durability. Enhanced surface treatments offer additional corrosion resistance, extending the operational life of the chains even in demanding working conditions.Q: What are the key benefits of using inverted tooth conveyor chains?

A: Key advantages include high tensile strength (with breaking loads up to 50 kN), low maintenance, customizable configurations, and exceptional lifespan. Their durable build and ready-to-install delivery mean lower operational downtime and increased system reliability.Q: Can these chains be supplied as per specific project requirements in India?

A: Yes, as a distributor, manufacturer, supplier, and trader in India, we provide both standard and fully customized inverted tooth conveyor chains tailored to precise project needs, ensuring optimal compatibility and performance for your conveyor system.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Silent Chain & PIV Chain Category

PIV Gearbox Chain

Price 20000 INR / Number

Minimum Order Quantity : 5 Pieces

Product Type : Other, PIV Gearbox Chain

Material : Other, Alloy Steel

Front Gear : High Strength Sprocket

Size : Standard & Customized Sizes Available

Inverted Tooth Silent Chain

Price 10000 INR / Meter

Minimum Order Quantity : 100 Meters

Product Type : Chains & Sprockets

Material : Stainless Steel

|

NATIONAL ENGINEERING WORKS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry